PETALING JAYA: Advanced scaffolding solutions will be increasingly important as construction sites grapple with tighter occupational safety and health regulations.

One of the solutions is from China-based Wenma Forming & Shoring Co Ltd, which has brought its over decade-long expertise to Malaysia with the goal of building a safe, healthy and environmentally-friendly working environment for the industry.

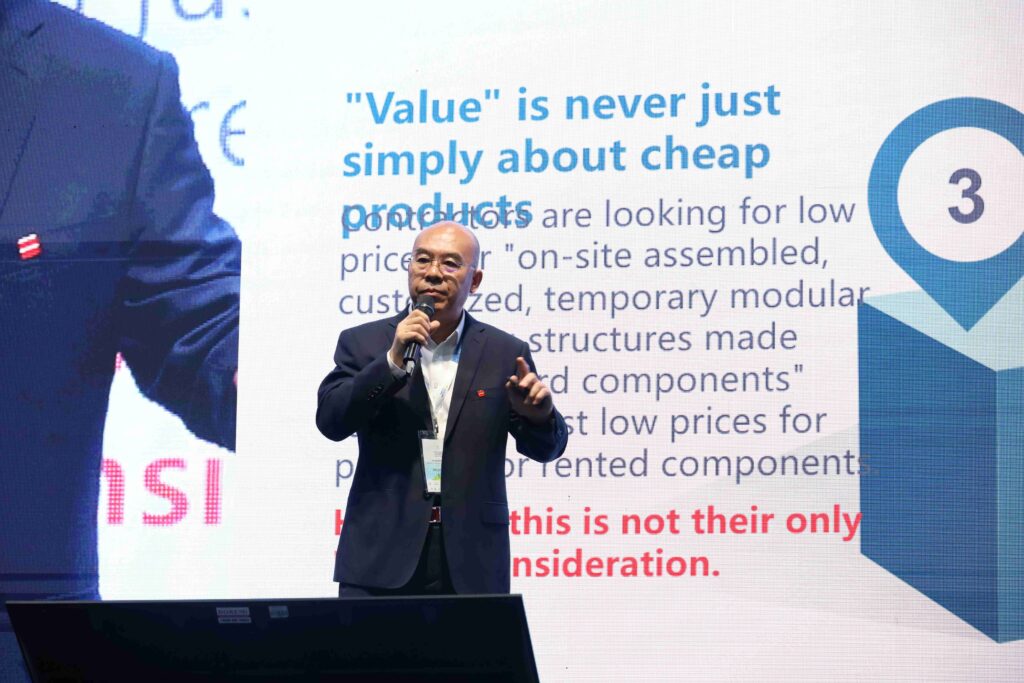

Through its local subsidiary Wenma Scaffolding Solutions and Services (M) Sdn Bhd, Wenma chairman Howard Hui Liu (pic) said he hopes to cultivate a culture of balancing safety and cost-effectiveness.

“Falling from heights is a significant risk faced by scaffolders every day, and account for almost half of fatal accidents in the construction sector.”

“This is because a large number of construction sites in Malaysia are still using very traditional methods to build scaffolds.”

“Combined with increasingly advanced projects with more complex design requirements, this will put workers at greater safety risk,” he said in a presentation at the Future Cities Summit in Kuala Lumpur on Tuesday.

Hui attributed this increased risk to the common contractor’s preference for cheap scaffolding and safety products to reduce costs, even though scaffolding works usually only make up a small portion of total project costs.

“We hope to help local contractors understand that achieving ultimate value is never just about using cheap scaffolding products.”

“We know that contractors look for low-priced, on-site assembled, customised, temporary modular scaffolding structures made from standard components, as well as the ability to rapidly erect and dismantle scaffolding.”

“This is why we put significant attention to the four major areas of components, engineering, equipment and construction as contractors should too,” he said.

On components, Hui said Wenma uses a systematic design with simple and fewer modular components to form complex structures to meet the specific needs of clients from different industries.

He added that Wenma’s equipment supply chain starts from material purchase, manufacturing and quality control, on time logistics service to every project, with these handled entirely by one team.

“Wenma also provides solutions to take care of any construction headaches by providing our engineers as well as health, safety and environment (HSE) specialists on site to render assistance.”

“This follows our philosophy of turning any sort of site hazard to safety, creating profit not just for the company but also value for society as a whole,” he said.

Through their efforts since the company’s founding in 2011, Hui said Wenma has helped change the construction industry in China to become safer and more efficient, and he hopes to do the same in Malaysia.

Among Wenma’s efforts is bringing together its clients’ builders, engineers and contractors to discuss how to build efficiently and safely.

Contractors are also taught to adopt a seven-step toolbox meeting every day, during which workers’ method and risk assessment were conducted every day before work begins.

This includes the inspection of personal protective equipment such as safety harnesses, which exhibit wear and tear with use.

To this, Hui said Wenma set up the International Standard Training Centre in China, which has been accredited by the United Kingdom’s Construction Industry Scaffolders Record Scheme (CISRS), the preferred scaffolding qualification of some of the largest scaffold systems manufacturers worldwide.

“We believe scaffolding is not just a kind of intensive work, but about achieving efficiency, a way of life, and preserving the dignity and safety of those involved in construction projects,” he added.

For the original article follow this link:👉

https://www.thestar.com.my/news/nation/2024/10/27/scaffolding-solutions-to-elevate-contruction-safety